If you are using a .22LR rifle, sound reduction is only required for subsonic ammunition. It is quite straightforward to…

★ Win a Schöffel Country shooting coat for everyone in your syndicate worth up to £6,000! Enter here ★

All about sound moderators

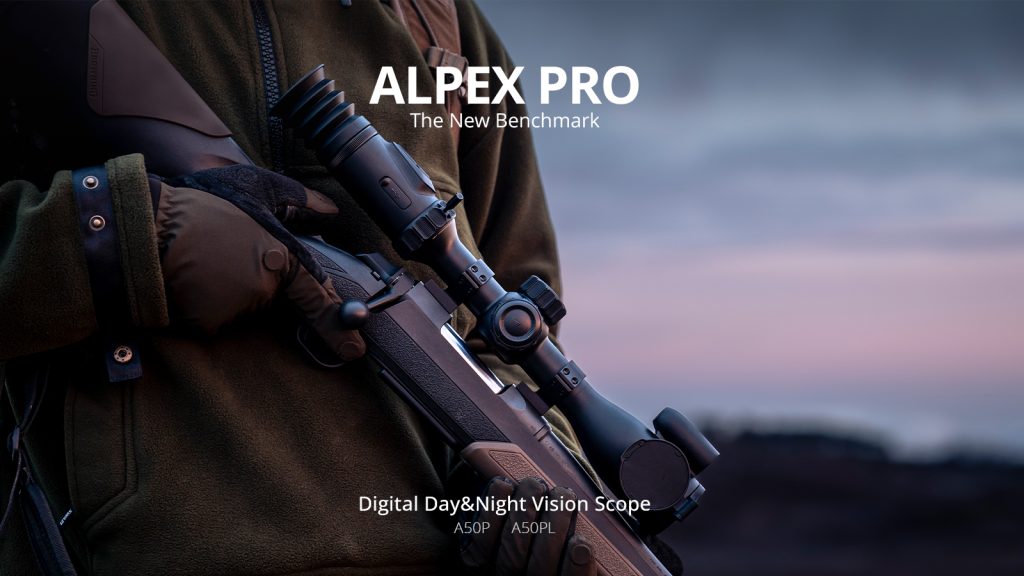

Even with a scope and sound moderator fitted the Finnlight 2 is super light, handles excellently and more importantly is accurate.

Even with a scope and sound moderator fitted the Finnlight 2 is super light, handles excellently and more importantly is accurate.

Sound moderators – or suppressors – are used to reduce the amount of noise and visible muzzle flash your firearm or air rifle generates when firing.

Moderators are sometimes referred to as silencers, but this is misleading as you cannot completely silence the report of a high-velocity bullet.

When the rifle is fired, two sounds are heard if you are close to the passage of the bullet. The first is the supersonic crack of the bullet passing, followed by the thump of the rifle discharging that follows shortly afterwards. It is the latter that gives away the direction of the firer, and the time between the two sounds also gives the observer an indication of how far away the firer is.

Whilst they used to be uncommon, sound moderators are now as standard as scopes when buying a rifle. However different shooters will require differently designed moderators. A stalker who shoots just a few times a year will manage with lightweight moderator whilst somebody looking for maximum noise reduction will need a larger moderator. Other shooters want to cut down on cleaning time by opting for a stainless steel version.

How to care for sound moderators

You need to establish a cleaning timetable for your sound moderators that co-ordinates with the amount you shoot. Fail to maintain your sound moderator and it will fit badly, could be dangerous and will ultimately fail.

Not only carbon but other products of combustion that can be harmful, especially in the type where the barrel forms one wall of the expansion chamber.

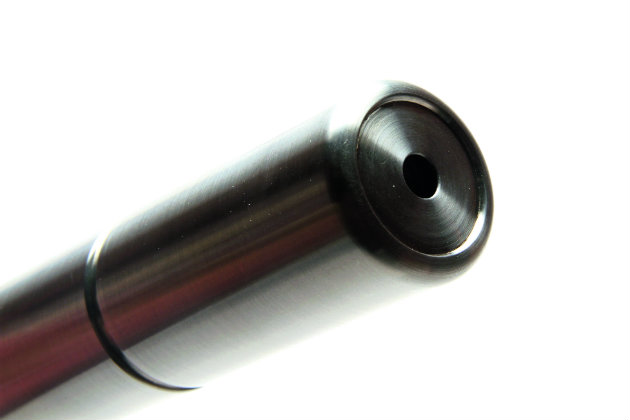

A sound moderator

Snug fit

A thread should have a snug fit to the moderator, but not so tight you exert any real force. It should engage the first section and glide down the threads using a single hand. The contact with the muzzle shoulders, if cut square, is enough to keep it from unscrewing and ensures perfect alignment to the bore.

This is as important for muzzle-mounted sound moderators as it is for an over-the-barrel model. In fact, with moderators that sleeve down the barrel, the rear supporting bush can also be a contentious issue.

If you fit an over-the-barrel moderator to your rifle and look at the gap at the rear of the moderator with the bush removed, you should see a perfect concentric equal diameter between it and the outside diameter of the bore. If you do not, then the thread is on the skew, so when you fit the rear bush and tighten the moderator fully, the barrel will be tensioned between the muzzle and this point, as the moderator tries to straighten the misalignment.

This is not good for the rifle and certainly detrimental to accuracy. If there is proper alignment, then a tight rear bush is beneficial; if not, a couple of thou clearance would be better suited.

You can ruin a good rifle very simply and quickly by having a bad threading job done.

Corroding issues

Problems with erosion and corrosion are caused to rifle bores from not taking off the moderator after shooting.

When you shoot the rifle, all that burnt powder and very corrosive gas residue is left in the moderator, either stuck to the baffles or loose in the body. The main products from combustion are carbon monoxide, water, carbon dioxide and nitrogen.

These can start to corrode the moderator from the inside out, but if the can is left on the rifle and put away standing upright, the moisture and corrosive mixture can and will migrate down into the first section of the barrel. If the rifle is left there unshot for a while, then pitting and rust to the internal surface of the bore will occur.

Sometimes it gets so bad that a moderator and barrel literally become fused together by corrosion.

Tips for looking after sound moderators

- After every shooting session take the moderator off the rifle

- Remove the can and let the rifle and moderator come to the same temperature as the room you are cleaning it in to stop condensation forming.

- At room temperature, wipe off any external water, muck and burnt gases or powder and then clean the rifle’s bore as normal.

- The moderator, if it is a sealed unit, can be gently knocked on a table-top to loosen any residue debris but, more importantly, before you put it away or back on a rifle, you should oil the interior surfaces to help eliminate corrosion.

- You can use Break Free or similar light gun oil, which leaves a fine protective film residue. If your moderator comes apart, disassemble and wipe out any moisture and clean off residual burnt powder and lightly lubricate it.

- Provided the threads are lightly greased with Moly Slide or Copa Slip the zero of the rifle will be unaffected if a moderator is re-assembled correctly after cleaning.

- Problems come from reassembling moderators with separate baffles in the wrong order, which can change the weight distribution, influencing barrel vibrations and thus impact. Or, if the moderator is screwed on at a different tension.

- Write a reference mark on the barrel and moderator to check correct alignment, so any disparity will become obvious.

- The actual material used in the construction of the moderator can lessen or greatly increase corrosion problems.

- Aluminium-constructed cans, though lightweight, can suffer from gas and flame cutting, resulting in erosion of the baffle edges and therefore loss of effectiveness. Also, aluminium on aluminium joints can fuse together and make disassembly almost impossible in some cases.

- A light steel-skinned moderator can be prone to rusting internally and externally, so keep it clean. Moderator covers can muffle noise from foliage rubbing against the can and help repel moisture – but make sure no water gets under the cover otherwise corrosion can begin unchecked.

- Next time you shoot your rifle and moderator combination, take it off after use at the very least, which will at least help stop corrosion starting at the crown and rifling of the barrel.

Q: Should I remove the sound moderator on my .22 rimfire after every use?

A: With a .22 rimfire, it is usual to leave it alone until there is a problem – 22 rimfires do not produce anything like the toxic concoction of acid and chemicals of a full-bore. In addition if you continually remove and replace the moderator there is a risk that it will not be correctly tightened, and so affect the zero.

As with all rimfires, I would give it special attention now and again: lubricate the screw threads and, more importantly, remove the build-up of crud, grease and unburnt powder that accumulates inside the moderator. Clean with methylated spirits with the baffles in place to avoid disturbing the internals.

If this does not remove the debris from the baffle edges then take it apart and give it a really good scrub. When you reassemble, check the zero and adjust it if necessary.

Five sound moderators on test

Bruce Potts puts five sound moderators for full-bore or centrefire rifles through their paces, looking at handling, performance and noise reduction.

The Jet-Z moderator has no rear bush, so is easy to fit into the muzzle’s thread

ASE UTRA JET-Z COMPACT

SUPPLIER: Sportsman Gun Centre

COST: on application

WEIGHT: 490g

The compact Jet-Z is a good noise reducer but, being steel, it will need cleaning to stay rust free

CALIBRE SIZES: It is available in a comprehensive array of thread sizes to fit any rifle with calibre’s up to 6mm or up to .30-calibre sizes. For smaller calibres, such as .22 Hornet, .222 Rem or .223 Rem, the smaller CQB version is suitable.

EASE OF FITMENT: 4/5 These sound moderators are muzzle mounted and have no rear bush, so it is easy to fit them to the muzzle’s thread. Available in all the popular thread sizes.

DESIGN AND HANDLING: 4/5 This unit measures 185mm in length and 40mm in diameter and weighs 490g. It used to weigh 560g and this reduction in weight is one of the Jet-Z Compact moderator’s strong points. It is steel so you will have rust internally if it is not cleaned occasionally. Though muzzle-mounted, it only adds 155mm to the rifle’s length and is a sealed unit with all welded joints, an effective design.

NOISE REDUCTION: 4/5 It deadens internal sound and removes that “ring” that other makers’ aluminium models have. The internals are designed around the characteristic “Z”-shape baffle arrangement, from which the name is derived. This makes use of all available space within the moderator to reduce noise by slowing down the expanding gases.

The Jet-Z Compact only adds 155mm to the rifle’s length

VERDICT: Good compact design that gives excellent decibel reduction for its size and good value for money.

TOTAL SCORE 12/15

Effective and light: MaccTecc on a .308 Winchester

MACCTECC V1

SUPPLIER: Edgar Brothers

COST: on application

WEIGHT: 215g

CALIBRE SIZES: You name it, the MaccTecc has a calibre for it.

EASE OF FITMENT: 4/5 An aluminium moderator that was designed wide to keep the overall length down when muzzle-mounted on a rifle. It is a sealed unit so needs little maintenance.

Shown next to a 450/400 nitro case for comparison only

DESIGN AND HANDLING: 3.5/5 The size, regardless of calibre, will be uniform with dimensions of 113mm long, 44mm in diameter and a weight of typically 215g. This weight is achieved because it is made of aluminium but has all the crucial internal vulnerable areas thicker to resist flame erosion. The MaccTecc is available in either all black or black outer with silver/grey ends to suit a stainless-steel rifle. The rear section has been designed with a taper to deflect reflected light away from the scope so is suitable for lamping. The internal baffl e system is complex, made from one machined CNC baffle stack from a series of cut rectangular vents in twin sets that progress up the moderator in four layers, with the vents orientated to form a stepped or opposing stack.

NOISE REDUCTION: 2.5/5 Good noise reduction for size but lightweight, leaves a ring to the report signature.

VERDICT: Will not increase the overall length of the rifle, with enough noise reduction in most calibres.

TOTAL SCORE 10/15

For those wanting a quiet and light moderator the SuperDome is it, shown on a Sand L Legacy 300 Blackout rifle

SCHULTZ & LARSEN MC44 SUPERDOME

SUPPLIER: Alan Rhone

COST: on application

WEIGHT: 280g

CALIBRE SIZES: Available in 6mm, 7mm and 8mm bore options as well as fitment to barrels up to a maximum diameter of 20mm.

Above left: Nice and compact size and light but effective is the essence of the SuperDome, shown next to a 300 Blackout round

EASE OF FITMENT: 4/5 The simple muzzle-mounted design can be changed into an over-barrel design by the conversion kit.

DESIGN AND HANDLING: 4/5 A muzzle-mounted moderator that gives a superb blend of small size, light weight and effective noise reduction. It weighs 280g and is 136mm long but adds just 120mm to the overall length and is 44mm in diameter. Its design allows the whole unit to be stripped or parts exchanged with a special “C” clamp. Its incorporates an aluminium construction for lightness and weather resistances. To avoid the dreaded flame erosion from the hot expansion gases on firing, Schultz & Larsen has inserted clever stainless-steel acoustic cones, “Hardcore”, to the centre of the baffles to extend their life, allowing them to survive repeated firings. Additional baffl es can be added at the front to tailor-make a sound moderator that works for a preferred load or calibre.

NOISE REDUCTION: 3.5/5 Effective for both supersonic and subsonic capability. I was impressed by how efficient and quiet the SuperDome was for an aluminium design.

VERDICT: Perfect for the weight-conscious shooter who wants a blend of good noise reduction and light weight, and the versatility to upgrade in the future.

TOTAL SCORE 11.5/15

Top choice – an excellent quality sound moderator that is built to last by a manufacturer with decades of experience

MAE T42 STS

SUPPLIER: Northern Optics

COST: on application

WEIGHT: 675g

CALIBRE SIZES: Available up to .243 calibre and then up to .30 calibre.

EASE OF FITMENT: 3/5 The T42 has a rear bush that needs to be profiled to match your barrel, though a new bushless version is in the pipeline.

The best on test for sound reduction and longevity due to its stainless-steel construction

DESIGN AND HANDLING: 5/5 It is an over-the-barrel design and is 265mm long with a 42mm diameter; only 128mm extends in front of the muzzle. This model is designed for larger-diameter barrels and can accommodate up to 25.5mm. The outer tube is 304L stainless steel, and the inner baffles and blast baffle are 100 per cent 304 stainless steel, making them very long-lasting. This is also a sealed unit for minimal maintenance and is the largest-diameter MAE moderator.

It is a sealed unit that needs little maintenance and is designed to fit large varmint barrels

NOISE REDUCTION: 5/5 This is achieved by the clever MAE inner baffle system and the overall weight of 675g that really deadens the noise from firing to a suppressed low resonance with no rolling echo.

VERDICT: If you want excellent noise reduction coupled with maximum longevity, the T42 fits the bill. It balances extremely well and is designed to last with its stainless-steel build. It’s certainly worth the money.

TOTAL SCORE 13/15

The Stalon W110 on test was quiet on cartridges up to .243 calibre

STALON W110

SUPPLIER: The Countryman

COST: on application

WEIGHT: 380g

CALIBRE SIZES: The Stalon design is calibre-specific but with the ability to separate and exchange thread or baffle sizes to match your rifle’s cartridge.

EASE OF FITMENT: 4/5 It is an over-the-barrel design moderator that only extends 100mm past the muzzle. This gives an already light rifle very little extra overall length and balances the rifle very well.

DESIGN AND HANDLING: 3.5/5 The Stalon range is aluminium-based. The W110 is 240mm long and 50mm wide but weighs only 380g. The rear section houses the threaded section to attach to the muzzle and behind this is an expansion chamber that envelopes the barrel when fitted. The front baffle stack section has a primary thick baffle that deflects the majority of the gases away from the bore axis and rearward, then through the vented forward baffles. This gives the gases time to flow through every part of the moderator and lose energy, and thus noise, by the time they exit the moderator.

The Stalon can be divided into two parts for cleaning or thread section replacement or baffle stack calibre changeover

NOISE REDUCTION: 3.5/5 Its large size makes the Stalon an effective noise-reducing moderator, especially on a Tikka T3X in .22-250 tested recently.

VERDICT: Overall very good noise reduction and balances well, with little weight addition for its size, and well priced.

TOTAL SCORE 11/15

Should I remove my sound moderator after every use?

I own a .22LR CZ for rabbits and I have a Parker-Hale sound moderator fitted. Should I remove it after…

Related Articles

Get the latest news delivered direct to your door

Subscribe to Shooting Times & Country

Discover the ultimate companion for field sports enthusiasts with Shooting Times & Country Magazine, the UK’s leading weekly publication that has been at the forefront of shooting culture since 1882. Subscribers gain access to expert tips, comprehensive gear reviews, seasonal advice and a vibrant community of like-minded shooters.

Save on shop price when you subscribe with weekly issues featuring in-depth articles on gundog training, exclusive member offers and access to the digital back issue library. A Shooting Times & Country subscription is more than a magazine, don’t just read about the countryside; immerse yourself in its most authoritative and engaging publication.