Win CENS ProFlex DX5 earplugs worth £1,149 – enter here

Boxall and Edmiston sideplate over-and-under review

Boxall and Edmiston's elegant new sideplate over-and-under, built and designed in Britain, is a shotgun worth waiting for

Peter Boxall was a director of gunmaking at Holland & Holland for a number of years and oversaw the development of the firm’s over-and-under Sporting range. This experience has served him well in designing Boxall and Edmiston’s over- and-under models. James Edmiston brings expertise in military armaments from his former position as managing director of the Sterling Armament Company.

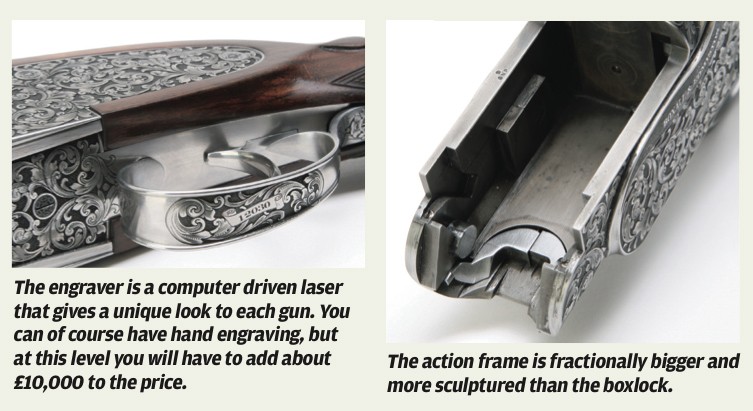

Boxall & Edmiston’s sideplate over-and-under was developed alongside the roundbody and is mechanically the same, though the action frame is fractionally bigger and more sculptured. It has bolstered fences above the sideplates that flow in to the front of the plate. At the knuckle the frame is highly rounded and this shape extends into the belly giving an elegance to the gun. the sideplate allows the machine engraver, an artist in his own right, plenty of room for expression.

Boxall & Edmiston have used v-springs at the bottom of the trigger plate either side of the trigger to push the hammers up from underneath. it’s an inspired idea as it leaves room for the inertia block to move freely without touching the mainsprings. the inertia block is also the sear lifter and selects the barrel through the safe button. It engages with the sear tails when the safe is pushed forwards. The fall of the hammers onto the back of the firing pins take forward the cocking cams, which in turn push forward the cocking rods that run, neatly hidden, along the floor of the action frame. The hammers are close together, so the line of the firing pins is as straight as possible to deliver maximum energy to the cartridge.

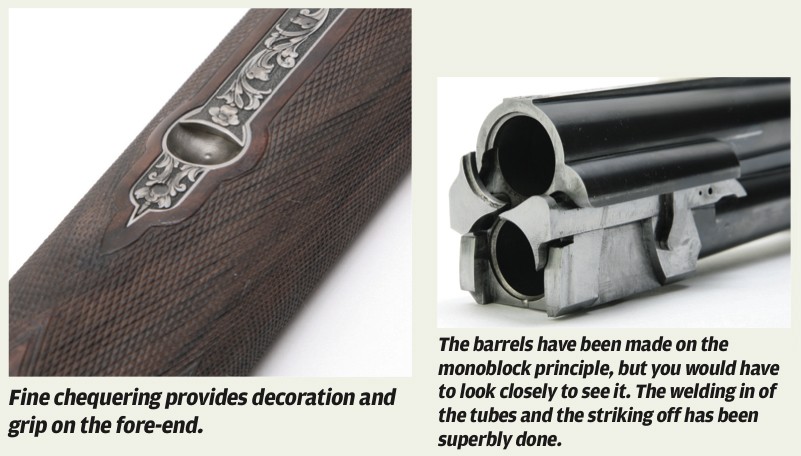

Each cocking rod is pushed back by a cam in the fore-end knuckle as the gun is opened, re-cocking the hammer ready for the next shot. Attached to each cocking rod is a trip rod, which engages each ejector trip toggle, housed on either side of the fore-end iron. The extractors are housed in the barrel monoblock and are directly sprung by coil springs. As the gun is opened the toggle picks up the toe of the extractor and is cammed to release the extractor at the point the gun is fully open.

Although widely accepted as the most efficient way to make over- and-under barrels, monoblock design is still regarded as inferior to demi-block by some gunmakers. Monoblock is where the breech end of the barrels is one piece with the tubes welded in place, so there are three pieces. Demiblock is where both tubes and breech ends are integral and the two pieces are soldered together at the action end – the over-and-under equivalent of chopper lump barrels. Pete Boxall believes the monoblock is more resistant to the stress of firing as there is greater surface area brought together on the joint between the barrels. In addition, the jointing on the face and bite is effectively on one piece.

The gun is a low profile action, which means it hinges on stubb pins or trunnions at the knuckle. The bolt locks into bites on either side of the monoblock at the breech face. There are also “draws” set into the side of the action wall to give the strongest possible lock up when the gun is closed.

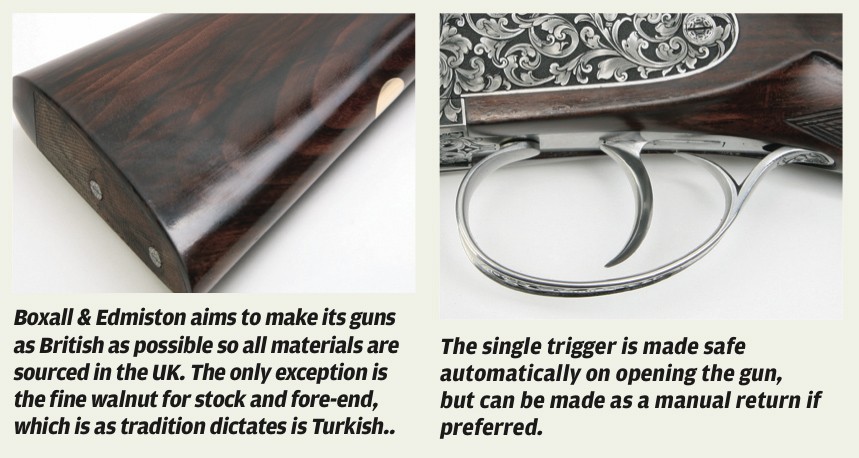

These guns are bespoke and Boxall & Edmiston will do everything in their power to accommodate your requirements, but there are some standard specifications. For example, chambers are 2 3/4 in with a long forcing cone. With the exception of barrel casting and blacking all the components of the gun are manufactured in house and the gun is put together and finished in the factory in Shropshire by Boxall & Edmiston’s own stockers and finishers.

Related Articles

Get the latest news delivered direct to your door

Subscribe to Shooting Times & Country

Discover the ultimate companion for field sports enthusiasts with Shooting Times & Country Magazine, the UK’s leading weekly publication that has been at the forefront of shooting culture since 1882. Subscribers gain access to expert tips, comprehensive gear reviews, seasonal advice and a vibrant community of like-minded shooters.

Save on shop price when you subscribe with weekly issues featuring in-depth articles on gundog training, exclusive member offers and access to the digital back issue library. A Shooting Times & Country subscription is more than a magazine, don’t just read about the countryside; immerse yourself in its most authoritative and engaging publication.