★ Win a Schöffel Country shooting coat for everyone in your syndicate worth up to £6,000! Enter here ★

Why every shooter needs a pheasant crowner

black labrador

black labrador

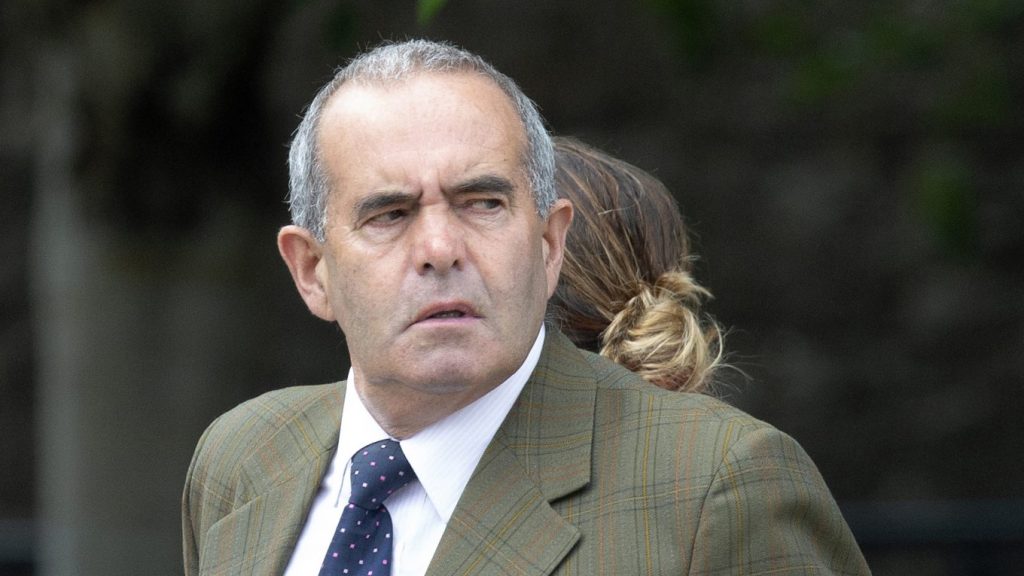

The very simple designs are often the best ones. I went to meet Dougie Bell, who invented the pheasant crowner, and John Relph of T. W. Relph and Sons Ltd, which markets it in conjunction with Solway Feeders.

The shining machine, fixed to the wall of a well-equipped game larder, is 53in long, 8in across from the outside of the screw fixing holes, and protrudes 12in out from the wall to the end of the wedge that holds the bird.

It is built in Cumbria by a precision engineer from high-quality stainless steel, so there is no risk of rust, and it is very robust; I could see it giving many years of service. Four substantial screws held the kit to the wall and it did not move. The simplicity of the process was a pleasure to watch and made me wonder why no one had thought of it before.

The whole process takes less than 30 seconds

Tidy crown

The whole process takes less than 30 seconds in the hands of a practised user and leaves a tidy pheasant or partridge crown.

We did the 10 or so birds Dougie had sourced the previous day in a few minutes and every one was as it should have been. There is nothing to stop anyone who wishes to utilise the processor in simply whipping off the legs for use in a variety of ways, so there is no waste at all.

Leaves a tidy pheasant or partridge crown

We only dealt with pheasants and partridge, however, and these are my thoughts; for those who like their duck breasts complete with the fat layer I did think it would take little time to pluck the breast, run a knife around the body cutting the fat layer below the breast line then treating it in the same manner in the machine. I am pretty sure with a little practice it will then leave you with a duck crown complete with fat. But don’t blame me if it doesn’t — I think it is worth a try. (Read our pheasant recipes here.)

The pheasant crowner costs £495 plus VAT. For professional processors, syndicate members — who could pop £50 into a kitty and buy one for the shoot — or the thousands now utilising game for their own use, friends and family, this machine is an ideal addition to the tool kit for dealing with many of the birds we shoot. It is impressively quick.

Ready for cooking or freezing – neat and tidy pheasant crowns

How the pheasant crowner works

- Hold the body of the bird in one hand and one wing in the other. With one movement, draw the wing over the blade close to the body and remove. Do the other wing the same way.

- With a thumb, press into the skin of the bird just above the crop and pull the crop down, exposing the cavity under the breastbone.

- Using the opening, push the bird, breast up, on to the wedge that protrudes from the shaft.

- Peel the skin right down either side of the breast, dislocating the legs in the same downwards motion.

- Using the foot pedal, press down while holding the breast of the bird with one hand and catch hold of the remainder of it when it parts company from the breastbone with the other.

This article was originally published in 2020 and has been updated.

Related Articles

Get the latest news delivered direct to your door

Subscribe to Shooting Times & Country

Discover the ultimate companion for field sports enthusiasts with Shooting Times & Country Magazine, the UK’s leading weekly publication that has been at the forefront of shooting culture since 1882. Subscribers gain access to expert tips, comprehensive gear reviews, seasonal advice and a vibrant community of like-minded shooters.

Save on shop price when you subscribe with weekly issues featuring in-depth articles on gundog training, exclusive member offers and access to the digital back issue library. A Shooting Times & Country subscription is more than a magazine, don’t just read about the countryside; immerse yourself in its most authoritative and engaging publication.