Shooting

The history of Webley air rifles

Would you like to speak to our readers? We offer sponsored articles and advertising to put you in front of our audience. Find out more.

Ask any airgun enthusiast born in the 1940s or 50s about Webley & Scott premium grade air rifles and the Webley Mk3 will be mentioned without hesitation, while the previous generation may instead recall the Webley Mk2 Service. Both were very fine air rifles, which will be examined in some detail within this two-part article, including their early history.

Whilst Webley were very much the UK market leaders in air pistols from the 1920s, BSA had dominated the air rifle scene from 1905 with their Lincoln Jeffries-inspired fixed-barrel underlever rifles.

However, in 1925 Webley launched their Mark 1 air rifle, different to contemporary BSAs. A compact, exquisitely made little rifle weighing just 5¼ lb, it had a strong family resemblance to the Mk1 air pistol of the time.

Not just air pistols

It further exploited the Johnstone & Fearn patent, having the barrel mounted on top of the cylinder.

Releasing the top catch and easing the barrel downwards pulled the piston forward until the sear engaged. Then, after returning the barrel, the piston travelled rearwards when the trigger was pulled.

The barrel catch (and safety catch) were very like the Mk1 pistol, but the piston had phosphor bronze piston rings like the Mk2 air pistol. The rifle was only 34in long with a 19in barrel, but the walnut stock was of adult proportions and balance was good.

With no wooden forend, holding onto the ironmongery was the order of the day with this gun and contemporary BSAs. Like the pistols, the barrels were interchangeable so that both .177 and .22 calibres could be possessed in the one gun. Open sights were fitted, with provision for vertical adjustment of the rear sight. Windage was achieved by drifting the foresight laterally in its dovetail. Production ran until 1932, but only about 1,500 were made, many of which were exported. Whilst I’ve owned, repaired and restored several Mk2 rifles, I have not had the pleasure of owning or working on a Mk1.

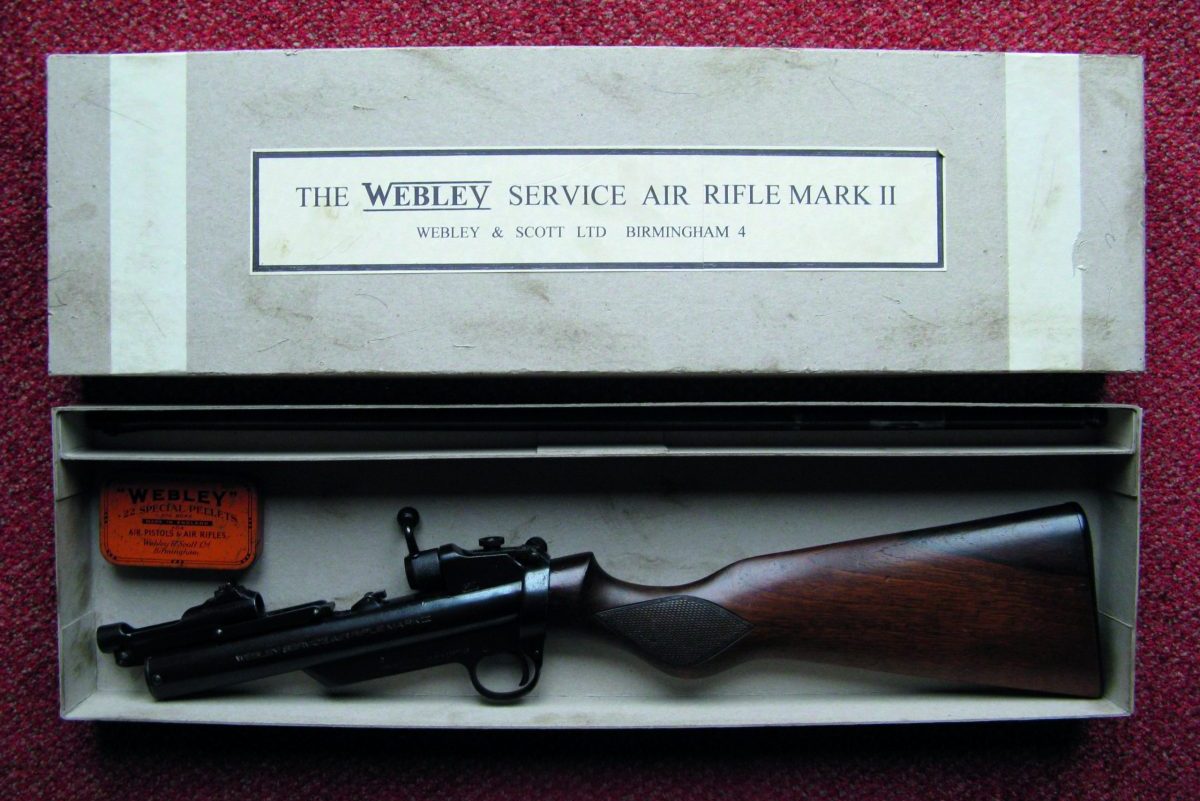

The Webley Mk2 Service Air Rifle (3rd Series) was a well-balanced gun that was extremely well made, but it was complex and expensive

To learn more about this model, and other Webley air rifles, I can highly recommend Christopher Thrale’s book Webley Air Rifles 1925 – 2005 which I have referenced in the preparation of this article, including the use of Mr Thrale’s own ‘Series’ numbers for the Mk2.

The Mk2 was introduced in 1932 and was later subject to various improvements, to culminate in the 6th series, with production ending in 1947. The greatest volume was of the 3rd series, of which about 9,000 were made of the grand total numbering around 16,300. I should mention how the ‘Service’ part of the rifle’s description hints at Webley’s early aspirations for use of their rifle in training by the military. This appears not to have been achieved, but MOD contracts could have increased sales volumes and profitability considerably.

The Mk2 Service Air Rifle was an excellent product which, unlike the Mk1, had the performance to be a serious rival to the BSA underlever rifles of the day. Whilst the design concept was similar to the Mk1, there were numerous significant differences. The interchangeable barrel feature remained and now included a .25 calibre option as well. The barrel didn’t need to have the pivot removed to enable another barrel to be fitted, as it could be readily slid out of the carriage sleeve into which it was mounted after pressing a spring-loaded button on the side of the sleeve. In contrast, early Mk2s had, instead, a rather fragile barrel retaining clip.

The flip-up aperture rear sight enabled precision shooting before the days of telescopic sights on an airgun became commonplace

The open, turret-pattern rear sight was mounted on the sleeve, but, very significantly, all Mk2s were fitted with a flip-up aperture rear sight as well. This sight alone, on the 3rd series, had almost as many component parts as a contemporary Webley Junior air pistol in its entirety! The breech arrangement was very different from that on the Mk1. After the bolt handle is lifted and rotated anti-clockwise, the barrel is released, enabling the gun to be cocked.

Closing the barrel drops the deep annular groove at the breech end into a cavity. Rotating the bolt handle back to its closed condition then causes a collar to draw the barrel backwards into the leather breech seal by virtue of the Webley ‘patent screw grip’. This arrangement neatly overcame the air leakage which could occur once a breech seal became worn on the Mk1 rifle.

An accurate rifle

The Mk2 had an advertised weight of 6½ lb with an overall length of 41½in. The barrel, at 25½in, was much longer than optimal for peak performance, but did provide for a long sight base. The rifle featured a chequered walnut stock with a horn butt plate (steel on the Mk1). The Mk2 was much more powerful than the Mk1, being capable of producing, in my experience, up to about 10 ft-lb of muzzle energy in .22 with Webley or Wasp (5.6mm) pellets. In their brochure, Webley showed .22 pellets having been fired at an iron plate which were shattered, even at a range of 40 yards. The only circumstance where I have been able to replicate this level of downrange kinetic energy has been with a rifle that was dieseling.

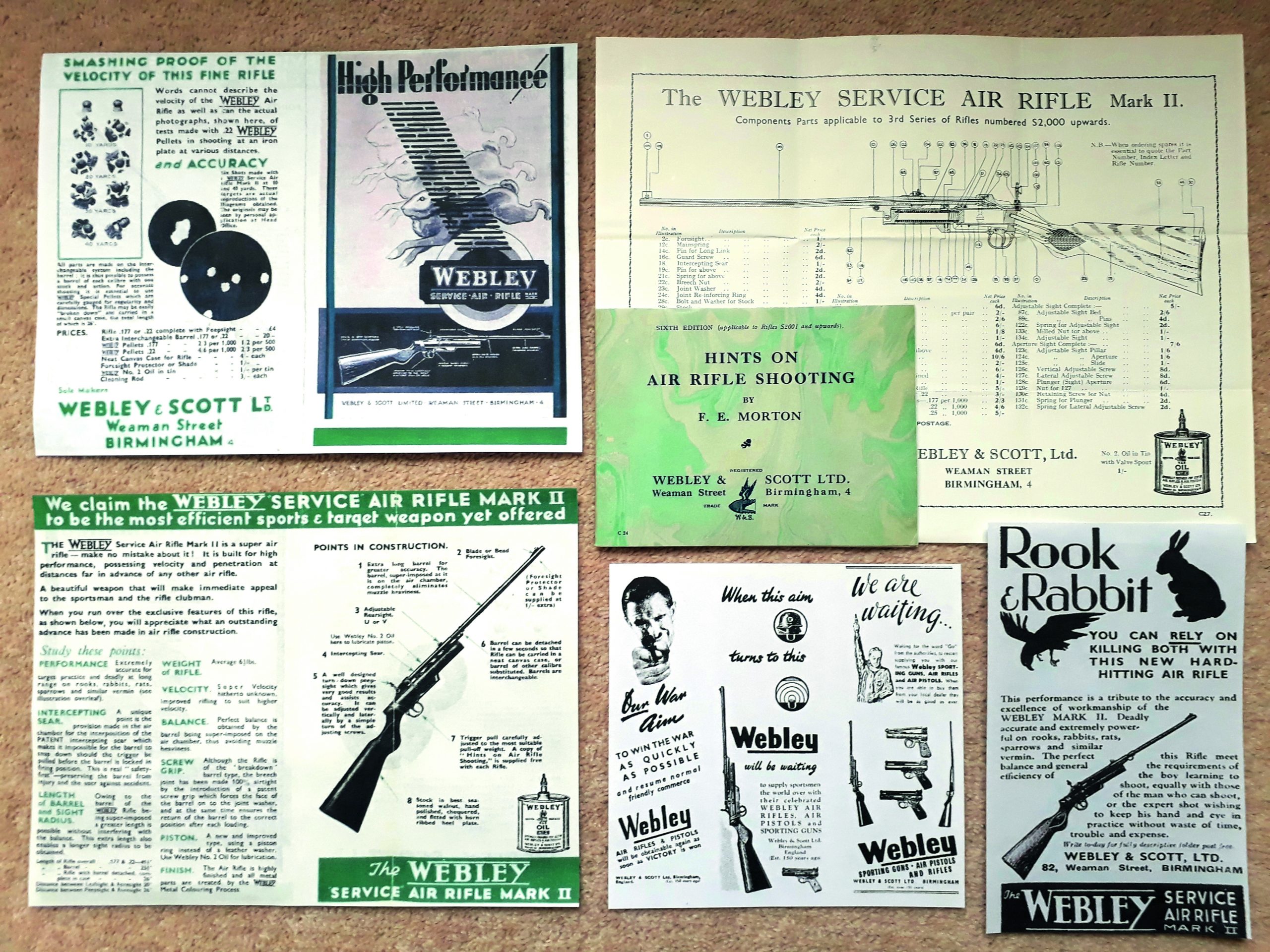

Webley claimed ragged single-hole accuracy at 10 yards and published targets indicating around 1¾in groups at 40 yards. The quality of the barrels and rifling make these accuracy claims entirely believable. Extraordinarily, though, early adverts suggested an 80-yard effective range, but this was a gross exaggeration that was not repeated in later advertisements.

This claim may have been partly responsible for complaints from customers of low power, which was mainly then attributed to lack of the correct lubrication of the cylinder/piston rings and batches of poor quality mainsprings. Advice on proper lubrication was given in the excellent booklet Hints on Air Rifle Shooting by F.E. Morton which was supplied with every rifle.

This view of the right-hand side of the action shows the bolt handle, open rear sight and interceptor sear

Although the Mk2 did not typically have a safety catch it did have a novel feature to protect against damaged fingers and mechanical failure if the trigger was pulled after cocking but before the barrel was closed.

This was in the shape of an intercepting sear which engaged as soon as the rifle was cocked and held the piston back until it was see-sawed out of engagement during the final few millimetres of barrel travel to the closed position. Whilst the trigger pull was not adjustable, the action was smooth and fairly crisp by the standards of the day.

High standards

The quality of craftsmanship and finish of the Mk2 was high indeed. The design was complex and consistent with what I have reported before for early Webley air pistols, very expensive to make. It used forgings and solid steel components with multiple machining operations, had a high component count and needed skilled operatives for the assembly work.

This meant that even when sold at premium prices, the Mk2 is reported never to have made a profit for Webley. These high costs were the reason for eventually replacing this model with the Mk3. The Mk2 had a deservedly loyal following, and a few are still in use by their first or second owners. Many spares are still available from airgunspares.com and they are a simple gun to work on – more on that later.

Being of a take-down design, removal of the barrel enabled the rifle, with or without additional barrels, to be carried in its compact cardboard box. Hard cases were available which bore a close resemblance to those for shotguns, with canvas and leather covering and partitions for accessories. Many cases you may encounter will be imitations. Soft canvas ‘leg of mutton’ style gun bags with separate stitched tubes for the barrels were also available from Webley.

So, in conclusion, the Mk2 Service is a unique, quirky masterpiece and an important piece of airgun history that can be a pleasure to own and shoot – buy well and enjoy!

Here are some contemporary advertisements and brochures along with FE Morton’s excellent booklet, which includes a parts diagram

Related articles

Shooting

Shotgun

Let’s bite the bullet

The ban on lead shot for all game shooting is moving apace so it’s time to find the best eco-friendly ammunition that suits you and your rifle

By Time Well Spent

Shotgun

Shotgun buying guides

Starting out? Make sure it fits

If you’re buying your first clay gun, the right fit takes precedence – not good looks, the brand your mate’s got or even price – warns Paul Austin

By Time Well Spent

Manage Consent

To provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.

Functional Always active

The technical storage or access is strictly necessary for the legitimate purpose of enabling the use of a specific service explicitly requested by the subscriber or user, or for the sole purpose of carrying out the transmission of a communication over an electronic communications network.

Preferences

The technical storage or access is necessary for the legitimate purpose of storing preferences that are not requested by the subscriber or user.

Statistics

The technical storage or access that is used exclusively for statistical purposes.

The technical storage or access that is used exclusively for anonymous statistical purposes. Without a subpoena, voluntary compliance on the part of your Internet Service Provider, or additional records from a third party, information stored or retrieved for this purpose alone cannot usually be used to identify you.

Marketing

The technical storage or access is required to create user profiles to send advertising, or to track the user on a website or across several websites for similar marketing purposes.