Cartridge choice can create an interesting debate in all areas of shooting. From manufacturer and loads through to the size of cartridge and shot…

★ Win a Schöffel Country shooting coat for everyone in your syndicate worth up to £6,000! Enter here ★

Why the shot in cartridges should be made of gold

Lead has been used for shot and bullets for centuries; not because it is ideal in all applications but because it is the best compromise. It is cheap when compared to many other metals, heavy enough to maintain velocity and energy over relatively long distances and is soft enough not to damage barrels. What’s more, it is easily formed into bullets or shot.

How lead shot is made

The traditional way of making lead shot is with a shot tower. The tower method works because of a peculiarity of liquid, molten lead. When droplets of molten lead fall through the air they form into spheres, unlike other liquids which form into any shape from teardrops to shapeless blobs. Molten lead forms into spheres because of its surface tension, and this is improved by adding a dash of arsenic to the mix.

Lead shot being dropped in the shot tower at Gamebore

As the lead falls it cools and solidifies, and final cooling takes place in a bath of cold water at the base of the tower. The size of the lead droplets is determined by pouring it through a sieve at the top of the tower. The size of the holes in the sieve dictates the size of the shot.

This simple process was discovered by William Watts, a Bristol plumber, in 1782. He built the first shot tower, and during the 19th century the number of towers around the country proliferated. Early in the 20th century Eley built a 170-foot tower in north London, and the tower method remained the only practical way of making lead shot in bulk until the 1960s. Gamebore still use its 180-foot tower in Hull, which it claims, is the country’s last to be making high-quality shot.

William Watts’ rebuilt tower in Bristol

The harder the better

The harder the lead shot is, the more likely it is to pattern well. This is because it keeps its roundness better as it travels through the barrel’s forcing cone and choke, and therefore the majority of pellets in the load have the same, good aerodynamic qualities. Hardness is improved by adding small amounts of antimony to the lead, generally up to about four per cent.

The Bliemeister method

One of the problems with shot towers is that they are difficult and expensive to build and maintain, so what was needed was a shot-making machine which could be used in a conventional factory. In 1961 Louis W. Bliemeister of California patented such a machine. It always strikes me as odd that the inventor’s surname is incredibly close to the German term bleimeister, which translates as “lead master”.

In the machine Bliemeister perfected, molten lead is dripped from small orifices and allowed to fall approximately one inch into hot liquid. From there it runs down an incline, which is then allowed to fall a further three feet.

The first such machine in Britain was imported by the Danarms company in the 1980s, and was subsequently acquired by Eley Hawk when the Danish company got into difficulties.

Non-toxic shot

In the 1980s there was a worldwide move to ban lead shot, particularly for wildfowl shooting, and the race was on to find substitutes. The USA opted for a steel shot rule for waterfowl shooting, on the grounds that cartridges could be tested by game rangers using nothing more sophisticated than a magnet.

England took a more sensible view and ruled that inland and coastal waterfowl shooters, or any shooters whose shot would fall on to wetland or water, could use any of the accepted lead-free alternatives. Scots law was, and at the time of writing still is, more lenient in that it allowed lead for inland waterfowl shooting where the shot would not fall on wetland or water.

These are very brief explanations of the rules, and full details are available by going to BASC.

The alternatives to lead include steel, bismuth, tungsten alloys such as Hevi-shot, and tungsten matrix – tungsten powder embedded in plastic.

Can I use steel shot in my gun?

Some relatively low-powered steel shot cartridges can be used in guns with ordinary proof providing the chokes are no tighter than half. All other steel shot cartridges should be fired through guns which have been subjected to superior steel shot proof. This proof mark features a Fleur de Lys – a bit like the Boy Scout badge. Fortunately, most new guns on sale now have been tested to superior steel shot standards.

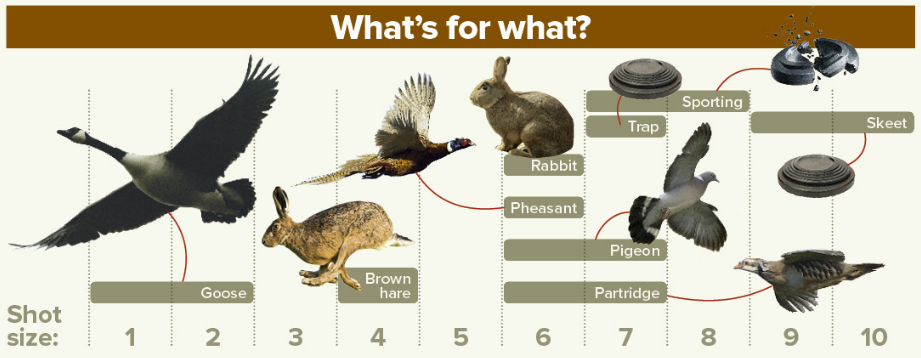

- For goose shooting where lead shot is allowed, shot sizes 1 and 2 are about right.

- A brown hare is quite a big animal, so is best shot with size 4.

- Size 6 is fine for pheasants and rabbits and is okay for partridges and pigeons, although size 7 can be used for these two birds.

- For clayshooting, size 7 is generally used for the trap disciplines, and most sporting targets are shot with sizes 7 and 8.

- Skeet, by rule, must be shot with sizes 9 or 10, and some very close sporting targets are best shot with skeet loads.

- When using non-toxic shot lighter than lead for field shooting, the general advice is to go up at least one size from the lead recommendation.

Classic game cartridges

Here we take a look at some classic game cartridges and see what is available with a fibre wad.

Steel shot cartridges review

Steel shot cartridges: Can steel shot be used for pigeon shooting? Lewis Potter tests a variety from his cartridge bag.

Non-toxic cartridges review

When it comes to wildfowling, not all non-lead duck loads have to be big and meaty!

Goose shooting cartridges review

Goose shooting cartridges: Looking to bag a goose or two and fancy popping off with a big magnum load?

Pigeon shooting cartridges review

Pigeon shooting cartridges review: This winter’s prolonged spell of cold weather has given our woodpigeon flocks a real hunger.

Related Articles

Get the latest news delivered direct to your door

Subscribe to Shooting Times & Country

Discover the ultimate companion for field sports enthusiasts with Shooting Times & Country Magazine, the UK’s leading weekly publication that has been at the forefront of shooting culture since 1882. Subscribers gain access to expert tips, comprehensive gear reviews, seasonal advice and a vibrant community of like-minded shooters.

Save on shop price when you subscribe with weekly issues featuring in-depth articles on gundog training, exclusive member offers and access to the digital back issue library. A Shooting Times & Country subscription is more than a magazine, don’t just read about the countryside; immerse yourself in its most authoritative and engaging publication.