Gear

Charging a PCP airgun – what do to and what to avoid

Would you like to speak to our readers? We offer sponsored articles and advertising to put you in front of our audience. Find out more.

The evolution of the airgun is a fascinating subject, and one aspect that always amazes me is the plethora of designs that exist, all in a concerted attempt to generate power and consistency. Pneumatic airguns are a big part of the equation, and while they aren’t exactly a modern invention there’s no doubting that they have enjoyed a period of unprecedented development in the last few decades. However, owning a PCP means being around highly compressed air, and this in itself shouldn’t be treated lightly. There are certain things to bear in mind, particularly best practice in terms of safety and the factors to consider in order to get the best from your rifle, so here is our guide on charging a PCP airgun.

Read here for advice on what you need to know about the terminology of PCP airguns, how to clean your PCP airgun barrel, and what to expect when you buy your first PCP airgun

Best practice for charging a PCP airgun

Most manufacturers use different valve designs. A Best Fittings quick plug is attached to an Air Arms adaptor on the left

Owning a PCP airgun means additional cost compared with other types of airgun since charging gear will be needed, be it a dedicated pump or air bottle. If you take the high-pressure air bottle route then safely store it well away from children.

Manufacturers will, in the main, supply the rifle with a filling adaptor which needs to be attached to the air line. There is very little standardisation of valve design, however, so most manufacturers will have their own design of adaptor.

For owners of several PCP airguns this can be frustrating as constantly unscrewing adaptors from cables and adding different ones is not only time-consuming, but may lead to air leaks, with threads becoming worn or dirty.

I recommend the Best Fittings Quick Coupler pack which is pre-attached to a quick-fit plug and enables the user to own adaptors for specific makes of rifle. Any adaptor/plug assembly can be snapped off and then, using a Foster style bayonet fitting, be coupled to the airline in a jiffy.

Charging a PCP airgun – safety first

A Foster-style snap-on valve

With PCPs it should never be forgotten that highly compressed air is contained within the system at all times. A pneumatic rifle with a silencer fitted can be extremely quiet while still generating full legal power. Don’t get complacent.

Likewise, DIY gunsmithing can be risky. Dismantling a spring-powered airgun can have pitfalls, but once the pressure of a part-compressed spring is taken into account it can be a satisfying project for those shooters possessing the right knowledge and tools.

By comparison, dismantling a PCP can be far more risky as it’s not easy to ensure that all the air has been expended from the system. If in doubt seek advice from a competent source.

Slowly open the valve

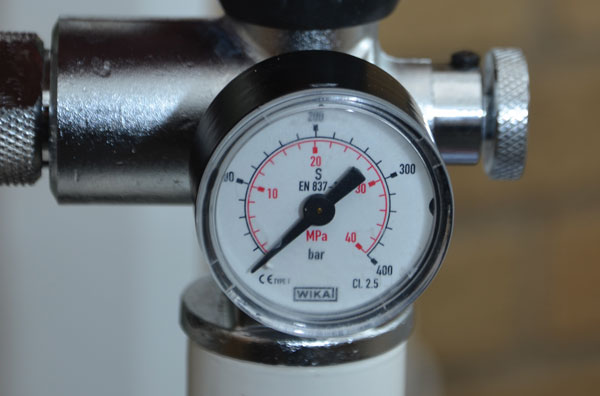

If you fill an unregulated gun too quickly you can easily overfill it

Many modern compressed air bottles come fitted with a controlled slow air feed for safety reasons. But if the bottle has a conventional full open flow then it’s good practice to open the air valve very slowly when charging a PCP.

This is important for two reasons. One: if you fill an unregulated gun too quickly you can easily overfill it to a pressure that is higher than recommended. Two: everything will heat up when fast expanding air is involved, and if the process is carried out too quickly the hot air will cool down as it settles, possibly to a lower than intended pressure.

What is the correct pressure?

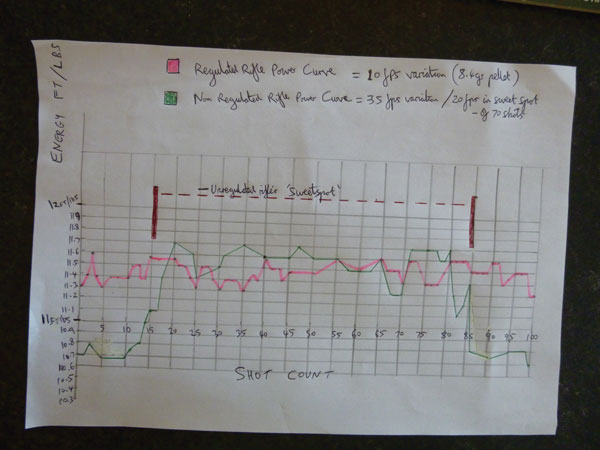

A chronograph will confirm the number and consistency of shots

Another major consideration when owning and using a precharged pneumatic is charging to the correct pressure. So let’s differentiate between a regulated and non-regulated rifle.

Regulated airguns

A rifle’s onboard regulator is designed to ‘fine-meter’ the air pressure and should result in tighter consistency from shot to shot along with many more shots per fill – a by-product of the system’s increased efficiency. Regulators typically operate at 70-90bar and providing the gun has more than this contained in its main reservoir all should be well.

The respective power curves of a regulated PCP set against those of a standard unregulated action

Non-regulated airguns

With a non-regulated airgun it’s a different ball game. The Air Arms S400 is a classic example of a non-regulated PCP. Air Arms quotes a fill pressure of 190bar, yet while you can fill to that pressure it’s likely the action will benefit from a lower initial fill pressure if ultimate consistency is required for competition use.

If the gun is intended for hunting or general target shooting, the manufacturer’s recommended fill pressure, which should offer a pleasingly large shot count, must be adhered to.

Charging a PCP airguns – finding the sweet spot

For HFT/FT enthusiasts and hunters who want to maximise and fine-tune performance, some judicious trial and error testing using a chronograph on the range will be time well spent.

We’re talking ‘sweet spot’ here – a term which has entered airgun parlance and refers to the fill pressure at which a particular gun will produce the longest string of super-consistent shots.

With no regulator fitted we are effectively charging one main air chamber. If, for example, we take a rifle that finds its sweet spot at 170bar (producing 65 ultra-tight shots) and charge this gun to 190bar, the knock-open valve has to work harder to open at the higher pressure.

This could cause the first 15-20 shots to be lower powered until the residual pressure drops to 170bar. At this point the string of 65 consistent shots will be produced before the velocities drop off in the normal way.

So to sum up: check your gun over a chronograph, note the fill pressures and fire a whole cycle until empty, recording all the velocities. If at any time the velocities have significantly changed check the residual pressure (relinking the gun to the air supply should no onboard gauge be present). Analyse the figures and it should be possible to ascertain the ideal fill pressure for the best run of consistent shots.

Safety check for fill probe valve

Insert the fill probe from the airline into the rifle’s inlet valve until it stops. Avoid any undue pressure on the cable if you are working at an awkward angle.

Ensuring a tight seal when charging a PCP airgun

Anyone familiar with using a PCP airgun will understand the frustration of finding an air leak in the charging kit. Achieving a perfect seal throughout the system is of paramount importance – and means adopting a subtle approach to airline connections.

Any filling adaptor must be securely attached to the air supply cable (beware of using excessive force which may damage screw threads). Hand tighten as hard as possible before slightly nipping up with spanners. Deploying a bonded washer or Dowty seal – effectively a contained high pressure ‘O’ ring – should ensure a perfect seal.

CORRECT: A Dowty seal is set in place along the thread to ensure a perfect air-tight seal

WRONG: Some connections can be metal to metal but achieving a perfect seal may be tricky

Related articles

Gear

KAHLES K540i THE GAME-CHANGER – 40X

KAHLES introduces the revolutionary K5-40x56i—a new era in long-range shooting optics. With a 40% wider field of view, an exceptionally comfortable eyebox, and precision performance even at 40X magn...

By Time Well Spent

Gear buying guides

It’s an extra set of eyes, day and night

A trail cam is an invaluable tool for learning what’s on your patch and, even more importantly, what it’s doing, as Will Pocklington discovers

By Time Well Spent

Manage Consent

To provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.

Functional Always active

The technical storage or access is strictly necessary for the legitimate purpose of enabling the use of a specific service explicitly requested by the subscriber or user, or for the sole purpose of carrying out the transmission of a communication over an electronic communications network.

Preferences

The technical storage or access is necessary for the legitimate purpose of storing preferences that are not requested by the subscriber or user.

Statistics

The technical storage or access that is used exclusively for statistical purposes.

The technical storage or access that is used exclusively for anonymous statistical purposes. Without a subpoena, voluntary compliance on the part of your Internet Service Provider, or additional records from a third party, information stored or retrieved for this purpose alone cannot usually be used to identify you.

Marketing

The technical storage or access is required to create user profiles to send advertising, or to track the user on a website or across several websites for similar marketing purposes.